By: Andy Odorzynski, Induron Protective Coatings National Sales Manager

The infrastructure bill recently passed into law allocates $50 billion dollars to improve the nation’s drinking water, stormwater, and wastewater infrastructure. The need is well documented as water systems throughout the country have been ordered to upgrade their systems via EPA Consent Decree.

The infrastructure bill recently passed into law allocates $50 billion dollars to improve the nation’s drinking water, stormwater, and wastewater infrastructure. The need is well documented as water systems throughout the country have been ordered to upgrade their systems via EPA Consent Decree.

The Impact on Engineers

As a result, municipalities and consulting engineers around the country have been inundated with water-related work motivated by the force of federal law to be designed and implemented with haste. Plus, specifying coatings for the diverse array of structures and exposure environments water assets are exposed to is an extraordinarily specialized task, which many engineers have never been trained for.

While pipe and water tanks each have dedicated AWWA standards devoted to qualifying and specifying coatings for potable water handling, treatment plant, wastewater and storm collection systems lack any such institutional guidance. As a result, engineers have been forced to turn to the coatings sales representatives who call on them to provide this expertise. While most of the time this is perfectly acceptable, some unscrupulous actors have worked diligently to put their sales ahead of the best interest of the project.

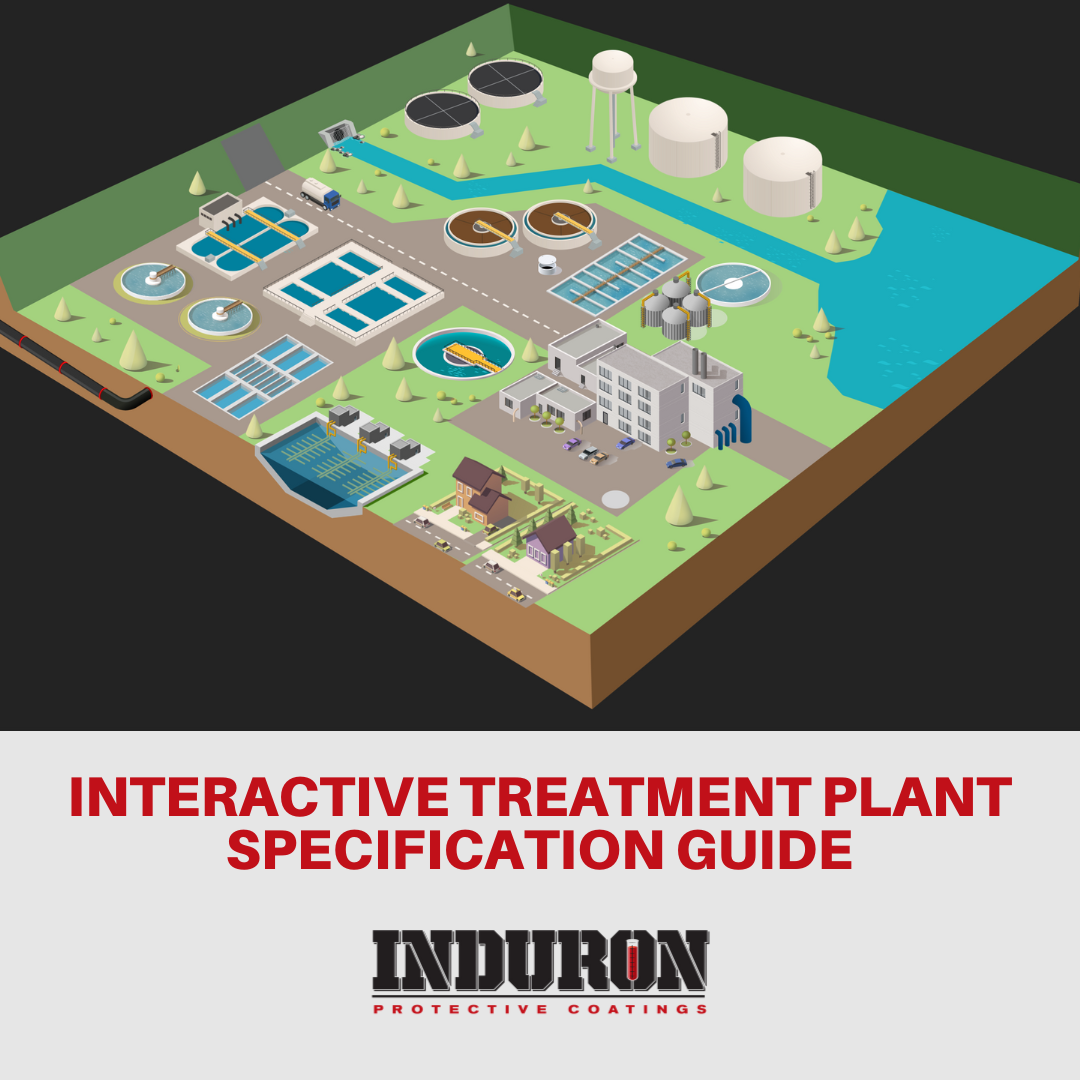

Induron’s Solution: An Interactive Treatment Plant Specification Guide

At Induron, we invest ourselves in the success, satisfaction and reputation of our customers. Our ultimate goals are to make their lives easier and discover innovative ways to add value to what they are doing. Sometimes that means developing a new product, and other times that means empowering our customers to make informed decisions.

Induron is excited to launch an interactive specification guide for treatment plants to equip engineers and owners with quick and thorough answers on which Induron coatings should be specified on assets throughout water collection, distribution and treatment facilities. After all, the need for this information is greater than ever, and we want to make it as accessible as possible!

We see this taking two forms: over specifying unnecessarily high film thicknesses to artificially increase the paint sold on a project, or conversely, underspecifying with a cheaper coating to ensure they are the cheapest option, which results in an underperforming project. We hope making appropriately-selected coatings specification information readily available will empower engineers to push back against any bad information.

Another important consideration when specifying treatment plants is to keep things simple for the applicators. We commonly see oddly complex specifications, which require different primers, liners, and finish coats for each asset at a treatment plant.

Induron Treatment Plant Coatings

As you explore Induron’s treatment plant coating options, you will notice the same coatings being listed on assets throughout the facility. This is very intentional. After all, we know Protecto 401 can handle the untreated influent coming into the plant. If our ceramic epoxy can handle that environment, we know it can handle the rest of the plant. You will notice ceramic epoxy linings like CeramaSafe 90 and PermaClean 100 used throughout the plant.

These adaptations of ceramic epoxy have been specially formulated for field application to waste and potable water processing assets, respectively. Keeping things simple for field applicators, inspectors, and future plant personnel performing maintenance helps keep job sites organized and free of mistakes. Plus, Induron’s ceramic epoxies are fully-compliant with the forthcoming NSF 600 changes.

We invite you to bookmark this site and use it as a go-to reference for properly-specified high performance coatings on your next water project. You can find the needed information for surface preparation, film thickness, products, and more for both steel and concrete structures.

If you’d like to learn more about Induron, our philosophy of innovation, or our products we would love to schedule a virtual or in person presentation. Contact us today.