With features for microbial resistance, increased film build, reduced permeability, and better adhesion than cohesion, ceramic epoxies are nothing short of phenomenal. While Induron now manufactures ceramic epoxies that are ideal for several end-uses applications, such as barrier coatings for water tanks, wastewater facilities and water treatment plants, ceramic epoxies were originally developed as a solution for lining ductile iron sanitary sewer pipe.

With features for microbial resistance, increased film build, reduced permeability, and better adhesion than cohesion, ceramic epoxies are nothing short of phenomenal. While Induron now manufactures ceramic epoxies that are ideal for several end-uses applications, such as barrier coatings for water tanks, wastewater facilities and water treatment plants, ceramic epoxies were originally developed as a solution for lining ductile iron sanitary sewer pipe.

The Original Ceramic Epoxy: Protecto 401™

In the 1970s, ductile iron pipe was introduced as a solution for sewer pipes, which virtually eliminated the breakage and leakage problems clay and cast iron pipe presented. However, due to relatively open joints, waste water leaked into the ground when the ground was dry and rainwater leaked into the pipe when the water table reached the pipe. To solve this problem, the U.S. The Environmental Protection Agency (USEPA) mandated the pipe joints be sealed.

This mandate created a situation where a sewer line effectively became much more concentrated, and therefore, more corrosive. The enclosed sewage can and will reflux acid in the crown of the pipe resulting in catastrophic pipe collapse. Consequently, it became obvious that a corrosion resistant pipe lining would also be required.

Working with pipe manufacturers and lining applicators, Induron perfected a unique epoxy lining using hollow ceramic particles to solve this problem. This became known as Protecto 401, and has since become the “gold standard” product used to line ductile iron sanitary sewer pipe. Protecto 401 Ceramic Epoxy Lining provides the reliability of cement mortar lining with the unequaled corrosion protection of novolac epoxy. Its unique qualities have resulted in performance unmatched by any other lining. Believe it or not, Induron has manufactured, sold and installed enough Protecto401-lined ductile iron sewer pipe for an 8-inch pipe to encircle the earth at the equator in the past 4 decades!

Ceramic Epoxies that Extend the Service Life of Potable Water and Wastewater Infrastructure

The proven success and superior performance of Protecto 401 prompted Induron to use the same ceramic epoxy technology to manufacture a line of several other innovative products that extend the service life of potable water and wastewater infrastructure.

TL70 Ceramic Epoxy

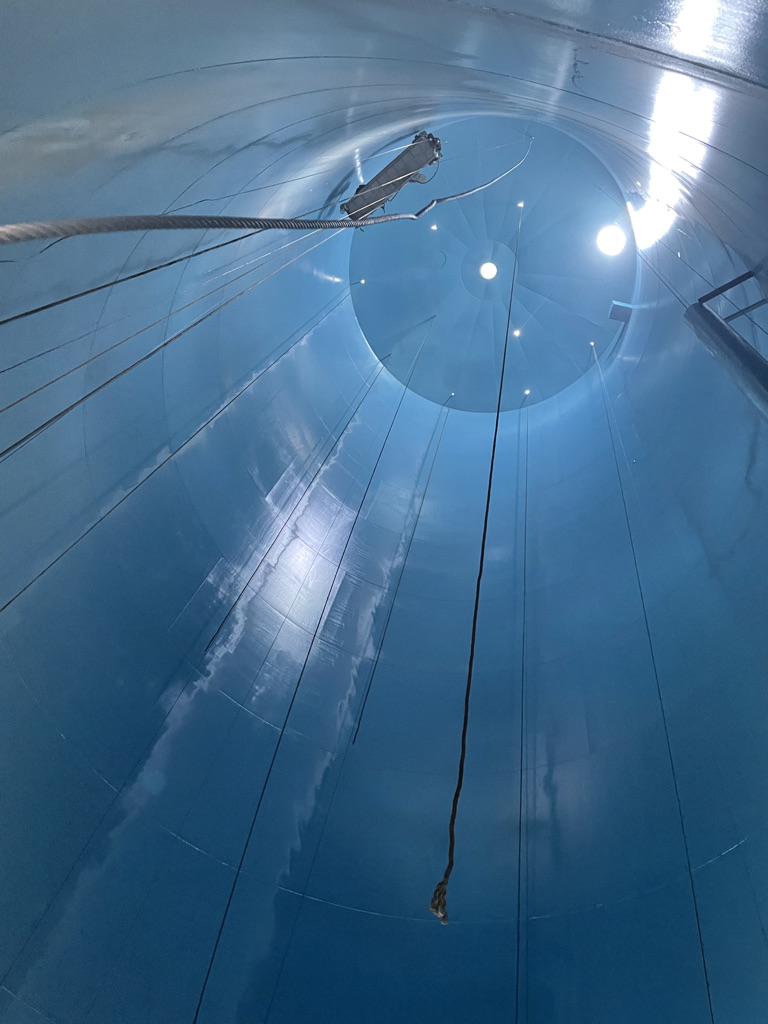

TL70 brings the unparalleled performance track record of our proprietary ceramic epoxy technology to tank lining projects. As a two-component, high build, high solids, densely cross-linked, ceramic modified epoxy, TL70 is the perfect option for asset owners who are looking for protection beyond that of a traditional thin-film epoxy lining, but who want to avoid the expense associated with 100% solids plural component application.

Ceramasafe 90 Ceramic Epoxy

Ideal for top coating a wide range of previously-painted surfaces, Ceramasafe 90 brings the track record of ceramic Epoxy performance to treatment plant assets. Ceramasafe 90 is a two-component, high solids, cyclo-aliphatic amine cured epoxy modified with a unique ceramic pigment package that provides outstanding permeability resistance and barrier protection. While most competitive products will add significant cost and complication to a project by requiring plural component application equipment, Ceramasafe 90 can be applied up to 40 mils in a single coat with standard airless spray equipment.

Permasafe 100 Ceramic Epoxy

PermaSafe 100 is a solvent free, immersion-grade lining incorporating ceramic pigment into an amine-cured epoxy resin for maximum corrosion protection of steel and concrete substrates immersed in sewage or exposed to many other aggressive environments. PermaSafe 100 is a unique and outstanding barrier coating formulated for the protection of steel and concrete in corrosive environments.

PermaClean 100 Ceramic Epoxy

Perma-Clean 100 is a fast-curing, 100% solids epoxy tank lining formulated specifically for protecting steel and concrete for potable water immersion applications. It provides enhanced edge retention, which improves corrosion protection on corners and sharp angles. Perma-Clean 100 not only offers unparalleled film build, ultra-low permeability, absolute minimal undercutting, and a non-ablative surface but also becomes dry to walk on in 10 hours at 70F. This allows for quicker inspection times, and can be placed into immersion service in 72 hours at 60F and above.

Induron Coatings, a 75 year old family run business has manufactured these ceramic epoxies for potable water storage tanks and water treatment facilities for four decades. Coming up on Jan. 1, 2023, the industry will undergo a change as the requirements NSF/ANSI/CAN 600 are adopted into the NSF Std 61 Criteria for Chemicals in Drinking Water standard. Fortunately, Induron’s decision to go HAPs free years ago left us with a fully-compliant catalog of NSF 61/600-approved ceramic epoxy products, which already have several decades of proven performance.

Interested in learning more about Induron’s ceramic epoxies? Visit Induron at Booth #3921 at WEFTEC or contact us today.