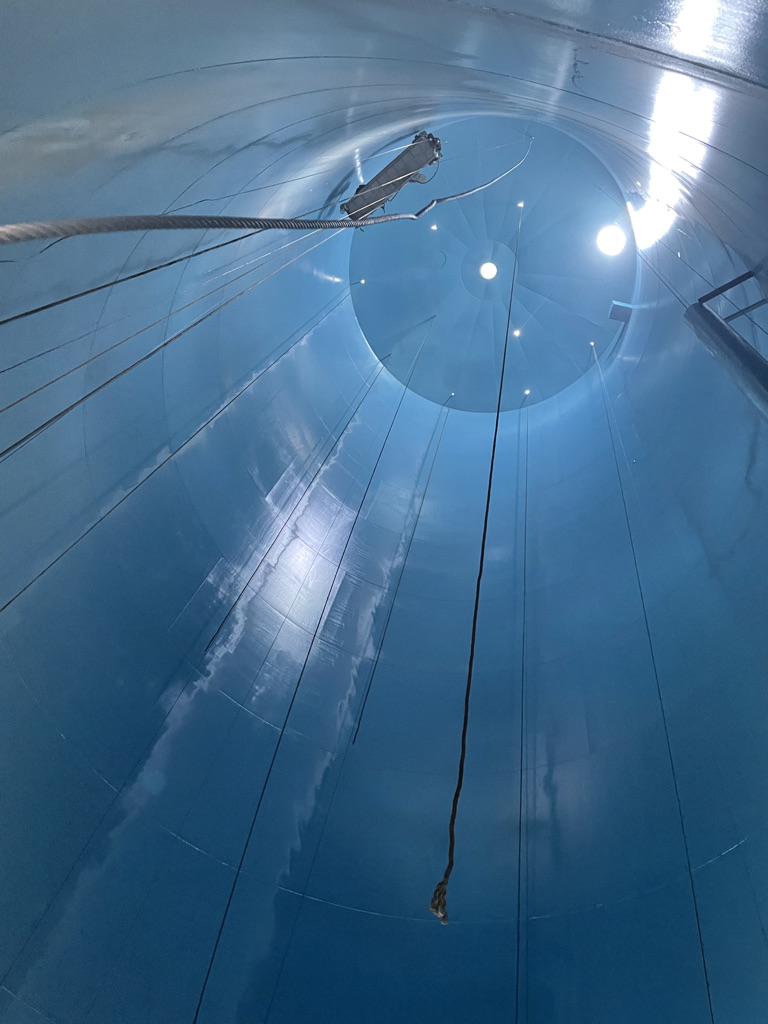

With features for microbial resistance, increased film build, reduced permeability, and better adhesion than cohesion, ceramic epoxies are nothing short of phenomenal. While Induron now manufactures ceramic epoxies that are ideal for several end-uses applications, such as barrier coatings for water tanks, wastewater facilities and water treatment plants, ceramic epoxies were originally developed as a solution for lining ductile iron sanitary sewer pipe. Continue reading Ceramic Epoxy: Extending the Service Life of Potable Water and Wastewater Infrastructure

With features for microbial resistance, increased film build, reduced permeability, and better adhesion than cohesion, ceramic epoxies are nothing short of phenomenal. While Induron now manufactures ceramic epoxies that are ideal for several end-uses applications, such as barrier coatings for water tanks, wastewater facilities and water treatment plants, ceramic epoxies were originally developed as a solution for lining ductile iron sanitary sewer pipe. Continue reading Ceramic Epoxy: Extending the Service Life of Potable Water and Wastewater Infrastructure

Category Archives: Wastewater Industry

Two Tanks, One Successful Coatings System

By: Tex Enoch, Induron Water Tank Market Manager

If it ain’t broke, don’t fix it, right? That was the City of Lancaster, PA’s philosophy when selecting a coating system for their new hydropillar tank.

If it ain’t broke, don’t fix it, right? That was the City of Lancaster, PA’s philosophy when selecting a coating system for their new hydropillar tank.

The coating system applied to its 7.5 million gallon ornamental ground storage tank back in 2020 was so successful that the city and their consulting engineer, AEERO Engineering, specified the same coating system for their new 2.5 million gallon fluted column “Hydropillar” that was completed this year (2021). Continue reading Two Tanks, One Successful Coatings System

Do You Know The Truth About the New NSF Water Tank Lining Standard?

By: Dr. Jeffrey Lackey, Induron Protective Coatings Technical Director

Benjamin Franklin once said, “Nothing is certain but death and taxes and regulatory changes.” Okay, you caught me. He didn’t really say anything about regulatory changes, but I’m pretty sure he would have if he had made that statement today. Continue reading Do You Know The Truth About the New NSF Water Tank Lining Standard?

Benjamin Franklin once said, “Nothing is certain but death and taxes and regulatory changes.” Okay, you caught me. He didn’t really say anything about regulatory changes, but I’m pretty sure he would have if he had made that statement today. Continue reading Do You Know The Truth About the New NSF Water Tank Lining Standard?

Defining Industry Challenges

By: Bill Seawell, Induron Technical Service Manager

Back in 2017, Induron’s National Sales Manager, Andy Odorzynski wrote an article emphasizing the need to define the challenges our industry faces in standardizing its approach to coatings in the water industry at large. Now, five years later, the water industry is still facing these fundamental issues. Below, I categorize, itemize and discuss some of these challenges. Continue reading Defining Industry Challenges

Back in 2017, Induron’s National Sales Manager, Andy Odorzynski wrote an article emphasizing the need to define the challenges our industry faces in standardizing its approach to coatings in the water industry at large. Now, five years later, the water industry is still facing these fundamental issues. Below, I categorize, itemize and discuss some of these challenges. Continue reading Defining Industry Challenges

What are Ceramic Epoxy Coatings?

Davies Hood, President and Owner of Induron Protective Coatings, recently discussed epoxy coatings, the advantages of ceramic epoxy coatings, how they’re manufactured, what applications utilities should use them for, and how the NSF 600 regulatory changes will impact the technology in an interview with Water and Wastes Digest. Continue reading What are Ceramic Epoxy Coatings?

Davies Hood, President and Owner of Induron Protective Coatings, recently discussed epoxy coatings, the advantages of ceramic epoxy coatings, how they’re manufactured, what applications utilities should use them for, and how the NSF 600 regulatory changes will impact the technology in an interview with Water and Wastes Digest. Continue reading What are Ceramic Epoxy Coatings?

Notes from the Field: NSF 600

By: William Seawell, Induron Technical Service Manager

Lately, in both the industrial coatings and water infrastructure industries, there has been much buzz about the upcoming changes to potable water lining standards. The standard we are all intimately familiar with, ANSI/NSF 61, is being replaced by ANSI/NSF 600. This change goes into effect January 1, 2023 and will have some effect on nearly all potable water linings installed in the United States. Continue reading Notes from the Field: NSF 600

Lately, in both the industrial coatings and water infrastructure industries, there has been much buzz about the upcoming changes to potable water lining standards. The standard we are all intimately familiar with, ANSI/NSF 61, is being replaced by ANSI/NSF 600. This change goes into effect January 1, 2023 and will have some effect on nearly all potable water linings installed in the United States. Continue reading Notes from the Field: NSF 600

Understanding Ceramic Epoxies and NSF 600

By: Andy Odorzynski, Induron National Sales Manager

For more than 35 years, Induron Protective Coatings has manufactured ceramic epoxies for various corrosive environments, including potable water storage tanks and water treatment facilities. On July 31, 2023, the industry will undergo a change as the requirements NSF/ANSI/CAN 600 are adopted into the NSF Std 61 Health Effects Evaluation and Criteria for Chemicals in Drinking Water standard. Continue reading Understanding Ceramic Epoxies and NSF 600

For more than 35 years, Induron Protective Coatings has manufactured ceramic epoxies for various corrosive environments, including potable water storage tanks and water treatment facilities. On July 31, 2023, the industry will undergo a change as the requirements NSF/ANSI/CAN 600 are adopted into the NSF Std 61 Health Effects Evaluation and Criteria for Chemicals in Drinking Water standard. Continue reading Understanding Ceramic Epoxies and NSF 600

Dirty Jobs: A Guide to Treatment Plant Coatings (Part III)

By: Bill Seawell, Induron Technical Service Manager

Water and wastewater treatment plants require a variety of industrial coatings due to their diverse service environments. From potable water immersion to aeration basins to exterior weathering systems, each service is different and requires a specialized coatings solution for corrosion protection. Continue reading Dirty Jobs: A Guide to Treatment Plant Coatings (Part III)

Water and wastewater treatment plants require a variety of industrial coatings due to their diverse service environments. From potable water immersion to aeration basins to exterior weathering systems, each service is different and requires a specialized coatings solution for corrosion protection. Continue reading Dirty Jobs: A Guide to Treatment Plant Coatings (Part III)

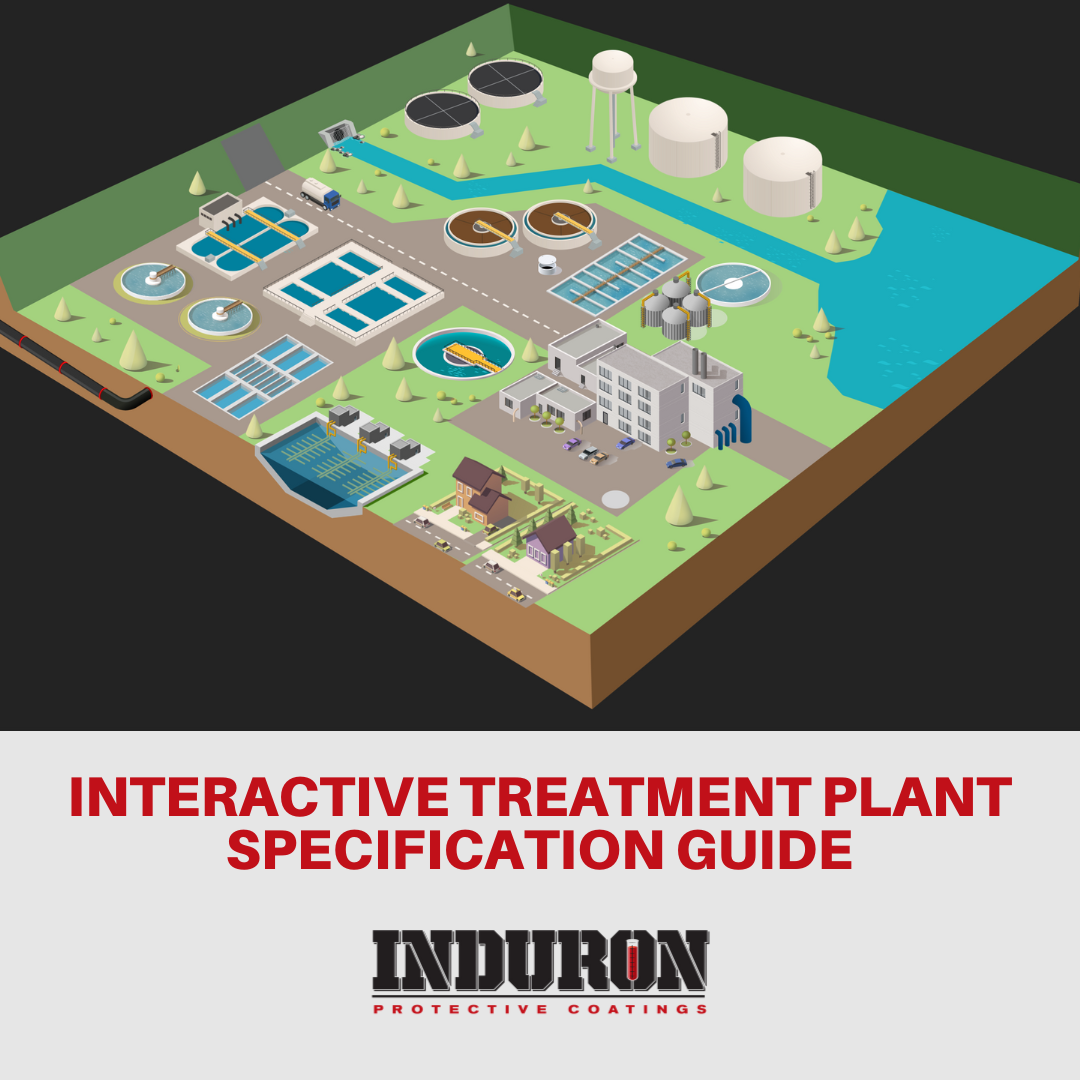

Empowering Engineers: An Interactive Treatment Plant Specification Guide

By: Andy Odorzynski, Induron Protective Coatings National Sales Manager

The infrastructure bill recently passed into law allocates $50 billion dollars to improve the nation’s drinking water, stormwater, and wastewater infrastructure. The need is well documented as water systems throughout the country have been ordered to upgrade their systems via EPA Consent Decree. Continue reading Empowering Engineers: An Interactive Treatment Plant Specification Guide

The infrastructure bill recently passed into law allocates $50 billion dollars to improve the nation’s drinking water, stormwater, and wastewater infrastructure. The need is well documented as water systems throughout the country have been ordered to upgrade their systems via EPA Consent Decree. Continue reading Empowering Engineers: An Interactive Treatment Plant Specification Guide

Dirty Jobs: A Guide to Treatment Plant Coatings (Part II)

By: Bill Seawell, Induron Technical Service Manager

By: Bill Seawell, Induron Technical Service Manager

Water and wastewater treatment plants require a variety of industrial coatings due to their diverse service environments. From potable water immersion to aeration basins, each service requires a specialized coatings solution for corrosion protection. The goal of this treatment plant coatings blog series is to inform owners and engineers of the best questions to ask when communicating with contractors and paint manufacturers to determine an ideal engineering solution. Continue reading Dirty Jobs: A Guide to Treatment Plant Coatings (Part II)