By: Dr. Jeffrey Lackey, Induron Protective Coatings Technical Director

The potable water tank industry went into a frenzied panic in 2021 when it was announced that the NSF standard for coatings for potable water was being changed to be significantly more restrictive on the levels of certain chemicals (NSF/ANSI/CAN61-2019.)

The potable water tank industry went into a frenzied panic in 2021 when it was announced that the NSF standard for coatings for potable water was being changed to be significantly more restrictive on the levels of certain chemicals (NSF/ANSI/CAN61-2019.)

Over the course of the year, we’ve informed our customers of the truth about the new standards, how they impact job sites, and ultimately, how the change is “old news” to Induron.

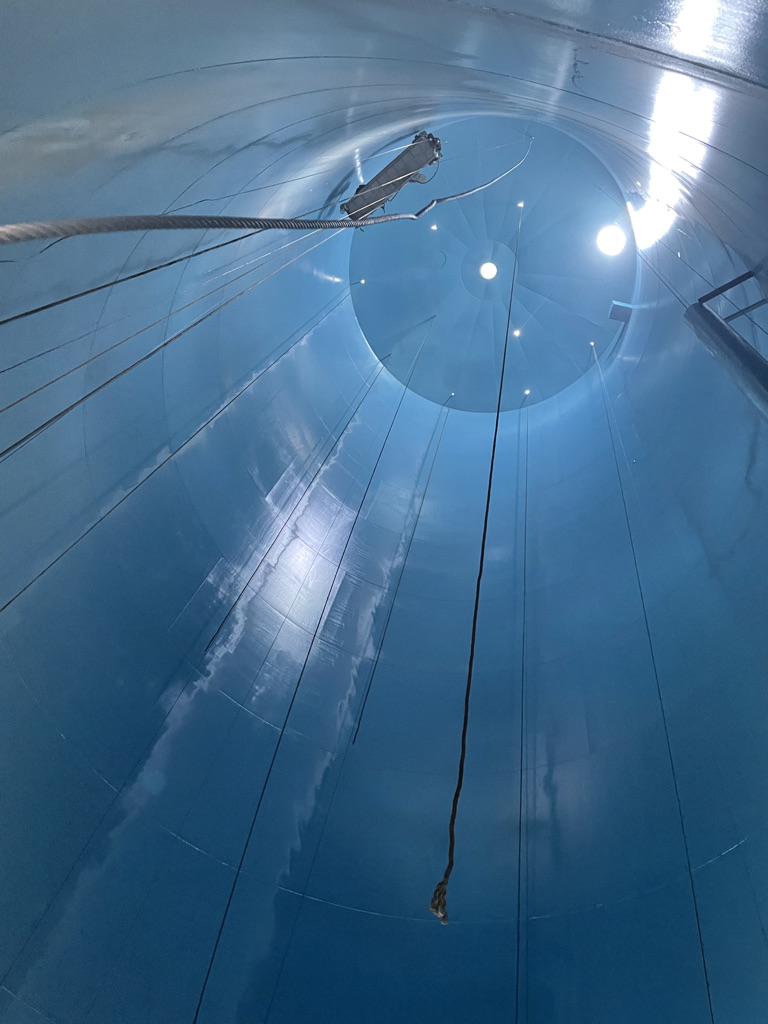

While many suppliers scrambled for solutions, Induron looked at the new standards, nodded, and pressed on with “business as usual.” Why? Because years before other companies were forced to reduce the levels of certain chemicals in their products for potable water, Induron had made the proactive decision to design and develop environmentally-friendly products that are as safe as possible for drinking water. Not because we were forced to do so by outside agencies, but because it was simply the right thing to do.

Now the agencies in charge of certifying products for potable water use, such as UL, are saying that many in our industry are complaining that they simply haven’t had time in the last couple of years to make the changes in their products required to meet the implementation date of January 26, 2023. They’ve petitioned the agencies to push the implementation date to the middle of the year–July 31, 2023. This change clearly has some people still struggling to meet these new standards. But again, Induron calmly carries on.

Induron’s Competitive Advantage: Market Focus and Proactivity

Change is inevitable, including (perhaps especially) changes in environmental regulations. But the inevitability of such changes allows a company with a clear vision to deal with such changes by being proactive rather than being forced into ruched, knee-jerk reactions. For Induron, the water tank market is a significant, targeted market and not a “side business.” Our specialized focus allows us to develop and plan proactively. Thus, while others spend their resources scrambling to meet new regulations, Induron can keep our resources focused on serving our customers and developing next generation technologies.

Interested in learning more about our products, which provide Reliable Protection Through Innovative Coatings? Contact us today.